James D. Englehardt, Ph.D., P.E., Principal Investigator

Tingting Wu, Ph.D., Postdoctoral Associate

Dept. of Civil, Architectural, and Environmental Engineering

University of Miamil

Water and wastewater treatment and conveyance account for approximately 4% of US electric consumption, with 80% used for conveyance. Net zero water (NZW) buildings would alleviate demands for a portion of this energy, for water, and for the treatment of drinking water for pesticides and toxic chemical releases in source water. However, domestic wastewater contains nitrogen loads much greater than urban/suburban ecosystems can typically absorb.

The University of Miami is currently conducting a four-year US National Science Foundation research project to demonstrate a low energy, low contaminant-discharge design for net-zero water buildings of the future. The purpose of this work is to develop design principles for net-zero water buildings of the future. In particular, a first design of a denitrifying urban NZW treatment process, operating at ambient temperature, pressure, and pH and providing mineralization of pharmaceuticals (not easily regulated in terms of environmental half-life), based on laboratory tests and mass balance and kinetic modeling, has been developed for testing. The treatment process is comprised of membrane bioreactor, iron-mediated aeration (Deng et al. 2012), vacuum ultrafiltration, and peroxone advanced oxidation, with minor rainwater make-up and H2O2 disinfection residual. Similar to biological systems, minerals accumulate subject to precipitative removal by iron mediated aeration (IMA), salt-free treatment, and minor dilution. Based on laboratory and modeling results, the system can produce potable water with moderate mineral content from commingled domestic wastewater and 10-20% rainwater make-up, under ambient conditions at individual buildings, while denitrifying and reducing chemical oxygen demand to below detection (< 3 mg/L).

Solution

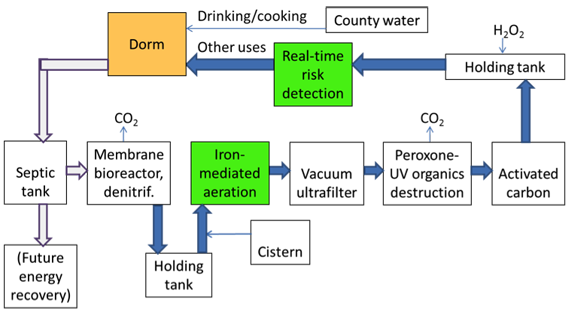

The current project demonstrates a low-energy, net-zero water treatment at a suite or apartment housing four student residents. The system has been designed by a team of University and industry partners, and demonstrated through laboratory and computer modeling studies. Construction and installation was essentially completed Fall 2012. The process avoids the use of high-energy reverse osmosis (RO) treatment through the use of county tap water for drinking and cooking; rainwater make-up; IMA; ultra-low-energy vacuum ultrafiltration; advanced oxidation treatment; and replacement of chlorine chemical disinfectant with hydrogen peroxide. For added redundancy and safety, finished water is designed to pass through two activated carbon filters in series. The treatment scheme is shown in Figure 1.

The IMA process was initially developed at the University of Miami using fibrous and powdered forms of iron. To reduce iron costs for application to net-zero water treatment systems, the process was modified to supply ferrous iron to the water via electrochemical reaction. Specifically, a small current is supplied to iron rod electrodes to convert iron metal to soluble ferrous ion. Initial reactions are:

Cathode: 6H+ + 3/2 O2 + 6e- → 3H2O

Anode: 2Fe → 2Fe2+ + 4e- → 2Fe3+ + 6e-

Laboratory experiments providing data for design of the field-scale system required a power supply to deliver 60~80 mA current at constant voltage of 2-5 V in a 1 L reactor. In such experiments, constant voltage DC power supplies (B&K Precision model 1635A, Tektronix CPS250) have been employed to supply the lower levels of current required.

In contrast with the laboratory system, the field-scale system requires a constant 2 A DC current at 4 ~ 10 V, delivered to twelve 2.54 cm (1 in) diameter iron rod anodes and cathodes. Therefore, one B&K Precision Model 1902 power supply (Figure 2) is used in the filed system as power supply for the IMA reactor (Figure 3). The reactor is a 56.9 L (15 gal) tank fitted with twelve 2.54 cm (1 in) diameter iron rod anodes and cathodes, across which a constant 2 A DC current is to be applied by external power source (4 ~ 10V DC).

Conclusions and Benefits

Based on laboratory tests and modeling it appears that a treatment process comprised of MBR, IMA, vacuum ultrafiltration, peroxone, and UV may be capable of producing moderate mineral-content potable water from commingled domestic wastewater at individual buildings, and mineralizing waterborne COD to below detection, at ambient temperature, pressure and pH. Specifically, laboratory results showed that approximately 80% nitrate and 80~90% phosphate was removed via IMA/vacuum ultrafiltration. If successful, the proposed process will be the first urban ambient net-zero water system, to our knowledge, designed to address the nitrogen balance in urban areas where most people live today. The proposed system would also be the first to substantially mineralize organics in process effluent. The capability of the B&K Precision Model 1902 to supply constant, high amperage current satisfied an important design requirement for this system.

System construction is in the final stages of completion, and the system is being run and stabilized with discharge of treated water to sewer for approximately one semester. System water will then be tested by an outside laboratory to ensure that all drinking water standards are being met. The water will then supply the residence hall unit for all uses except drinking and cooking, which will be supplied by county tap water. System water will be sampled and tested for quality at least three times daily and, in the event of emergency, water supply will revert to county tap water. As a result of continuous treatment and monitoring, the water is expected to be higher in quality than other tap water, though it will not be used for drinking by student residents during the research phase.

Planned future research includes the incorporation of the IMA process within the membrane bioreactor, and the development of electrochemical processes to improve net-zero water treatment system operation and maintenance. This work will also require high-performance DC power supplies.

Reference

Deng, Y., Englehardt, J., Abdul-Aziz, S., Bataille, T., Cueto, J., De Leon, O., Wright, M., Gardinali, P., Narayanan, A., Polar, J., Tomoyuki, S. (2012). "Ambient Iron-Mediated Aeration (IMA) for Water Reuse." Water Research, (in press).

Acknowledgements

The support of the US National Science Foundation (EFRI-SEED Award 1038257), the US Environmental Protection Agency, Engineered Control Systems, Inc., BioMicrobics, Inc., B&K Precision Corp., and RTI Supply for this work is gratefully acknowledged.

Figure 1. Urban Ambient Mineralizing Net-Zero Water Treatment System

Figure 2. Two B&K Precision Model 1902 power supplies located in the air-conditioned peroxone reactor room.

Figure 3. IMA-vacuum ultrafiltration process, under final construction; Electrodes shown (lower panel) stored in the bucket are to be installed in the IMA reactor on the stand, to be powered via one B&K Precision Model 1902.

Figure 4. Three Kobold Low Volume Flow Meters (powered by one B&K Precision Model 1902).