In March of 2009, the Stanford Solar Car Project team returned from a race across Australia. After placing 10th overall and 4th in their class out of a field of 40 competitors, Stanford acknowledged they needed to find a better way to tackle a different kind of curve that was far more vital than those their car's pilot encountered on the road -- the IV curve of a solar panel.

Part of a solar panel system are maximum power point trackers (MPPTs), which are “very high efficiency DC-DC converters used to trace the IV curve of a solar panel and return its maximum power point,” stated Nathan Hall-Snyder, a former team leader of the Stanford Solar Car Project. Through the MPPT system, they would be able to sample the output of the cells and apply a load that would derive the maximum power for any given environmental conditions.

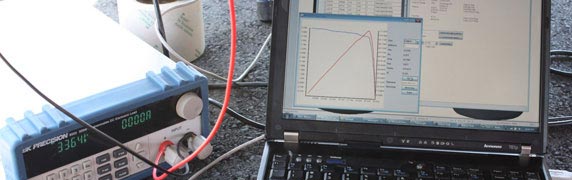

Thanks to donation of B&K Precision’s 8502 programmable DC electronic load, the Stanford team was able to test and characterize their DC-DC converters to better optimize their MPPT system. The DC load is essentially replacing the battery in their test. The team chose the 8502 due to its high voltage rating of 500 V, which fitted well with the battery pack used in their system that operated at a maximum voltage of 160 V.

Testing and modeling of solar cells is performed by sweeping the load current while measuring the voltage across the solar panel. This determines its IV characteristics with the purpose of generating accurate discharge curves for the battery pack.

By accurately characterizing their MPPTs, the Stanford Solar Car Project team was able to obtain the maximum possible power from their car’s solar panels, and effectively reduce I2R losses to transfer more power to their motor.

Foundation

Founded in 1989, the Stanford Solar Car Project is an entirely student-run, non-profit organization fueled by its members’ passion for environmentally sustainable technology. It’s a unique opportunity for Stanford students to gain valuable hands-on engineering and business experience while raising community awareness of clean energy vehicles. The team generally operates on a two-year design and build cycle and enters the finished car in a cross-continental solar race.

Members usually join SSCP as undergraduates with little to no engineering background and gradually build their knowledge while working on a vehicle. Coordinating a project of this magnitude also requires considerable management and planning, allowing students to develop these vital business skills in an engineering environment. With this approach, the team has fostered eight generations of award-winning vehicles, proving that a hands-on education in creative design and execution produces impressive results.

B&K Precision is proud to be a sponsor of the Stanford Solar Car Project.

IV trace generated via the 8502 with a homebrew program connected to the DC load's serial interface